Product Categories

|

SPECIFICATIONS |

Units |

CK6150 |

|

Swing over bed |

mm |

500 |

|

Swing over cross slide |

mm |

260 |

|

Distance between centers |

mm |

750/1000/1500/2000 |

|

Spindle bore |

mm |

52(Optional 80) |

|

Spindle bore taper |

- |

MT6 |

|

Spindle nose type |

- |

C6 |

|

Spindle speed steps |

- |

Manual 2 steps |

|

Spindle speed range |

rpm |

L:100-500 H:500-1800 (Optional 90-1800 stepless) |

|

Turret/tool post |

- |

Electric 4 position |

|

Tool size |

mm |

25 x 25 |

|

X axis travel |

mm |

280 |

|

Z axis travel |

mm |

750/1000/1500/2000 |

|

X axis rapid traverse |

mm/min |

6000 |

|

Z axis rapid traverse |

mm/min |

8000 |

|

Tailstock quill diameter |

mm |

65 |

|

Tailstock quill taper |

- |

MT5 |

|

Tailstock quill travel |

mm |

130 |

|

Main spindle motor |

kw |

5.5 |

|

Coolant pump motor |

kw |

0.09 |

|

Weight for 750 |

kg |

1800 |

|

Weight for 1000 |

kg |

1900 |

|

Weight for 1500 |

kg |

2000 |

|

Weight for 2000 |

kg |

2100 |

|

Dimension for 750 |

mm |

2200x1700x1750 |

|

Dimension for 1000 |

mm |

2500x1700x1750 |

|

Dimension for 1500 |

mm |

3000x1700x1750 |

|

Dimension for 2000 |

mm |

3500x1700x1750 |

STANDARD CONFIGURATION

1) System:GSK, servo motor and drive.

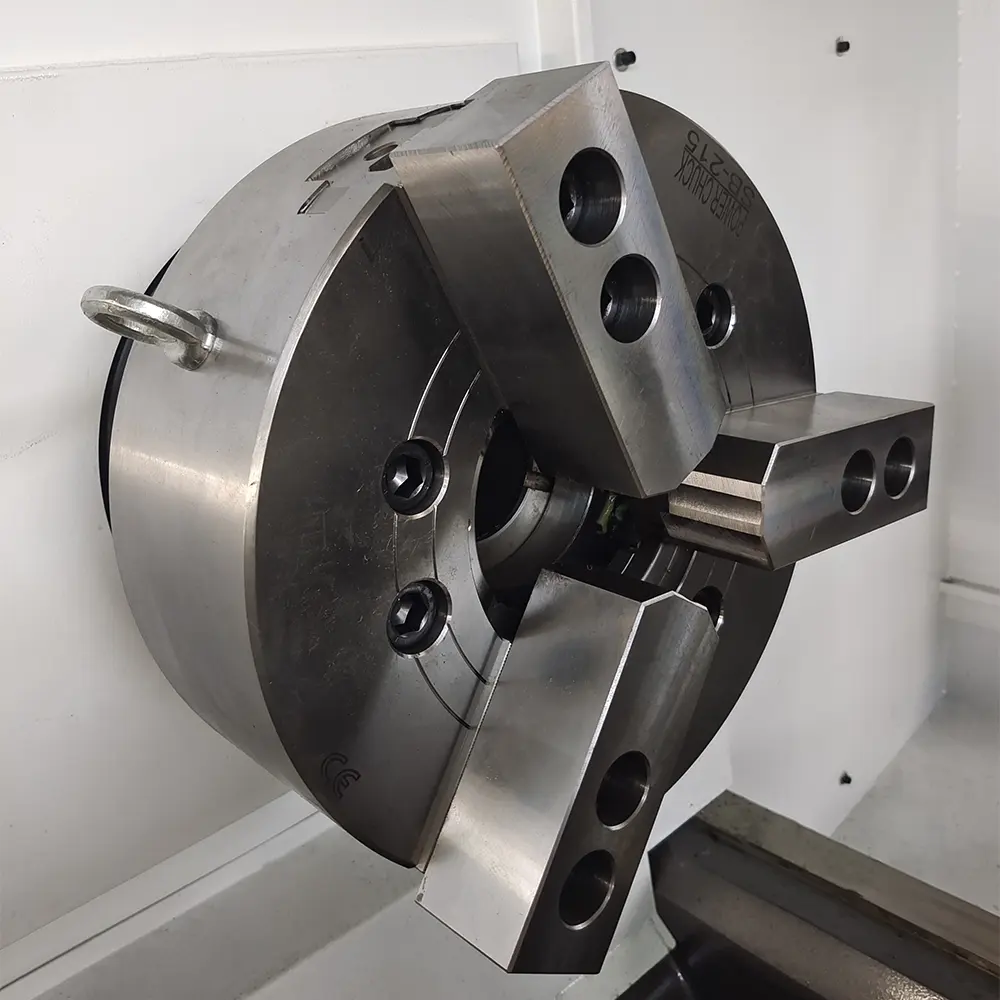

2) Manual 3-jaw chuck.

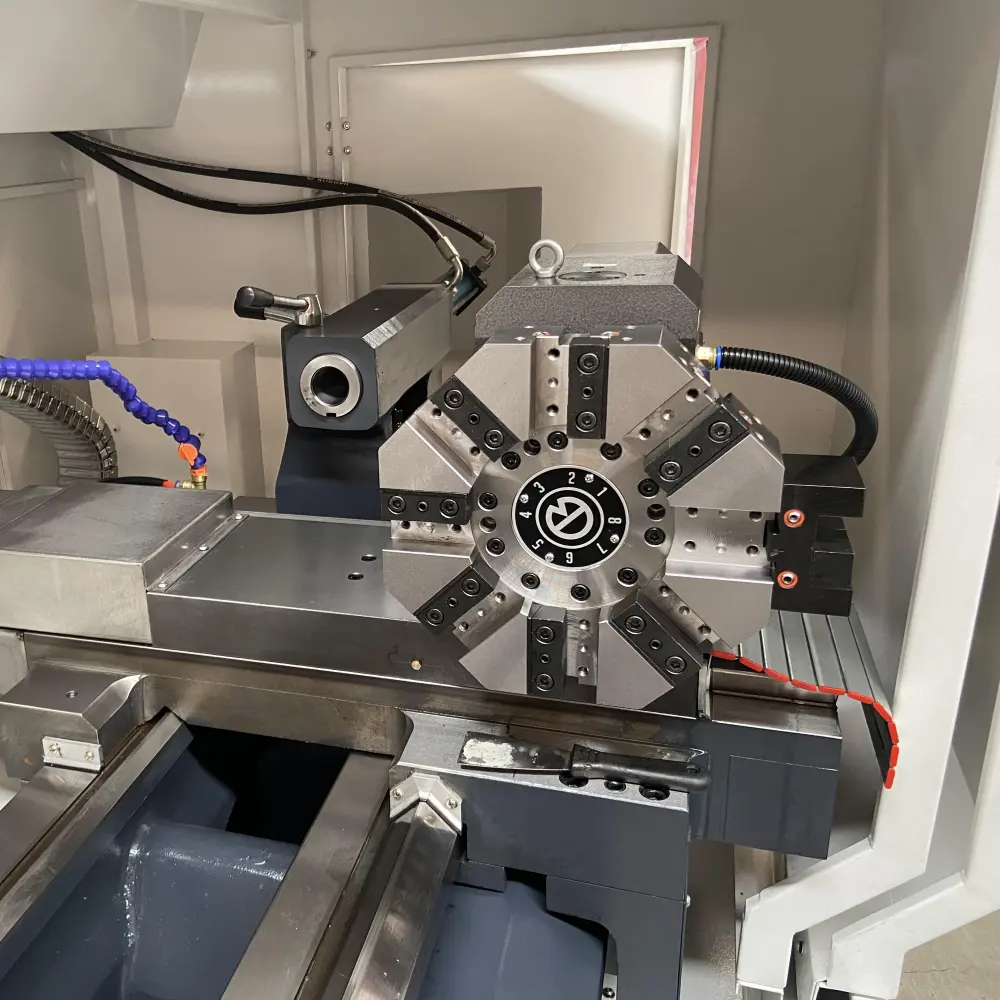

3) Four station electric tool post .

4) Manual tailstock;

5) Cooling system.

6) Lighten system;

7) Automatic lubrication system.

OPTIONAL CONFIGURATION

1) CNC system: Siemens, Fanuc, KND, etc。

2)Hydraulic chuck, pneumatic chuck .

3)Hydraulic tailstock, pneumatic tailstock.

4) 6/8station electric tool post.

5)Automatic bar feeder.