Product Categories

Please note: Due to the adaptability of the web page, you may not be able to see the parameters on your phone.

Please turn your phone sideways so that you can see the parameters.

|

SPECIFICATIONS |

Units |

CK6140 |

|

Swing over bed |

mm |

400 |

|

Swing over cross slide |

mm |

210 |

|

Distance between centers |

mm |

750/1000/1500/2000 |

|

Spindle bore |

mm |

52(Optional 80) |

|

Spindle bore taper |

- |

MT6 |

|

Spindle nose type |

- |

C6 |

|

Spindle speed steps |

- |

Manual 2 steps |

|

Spindle speed range |

rpm |

L:100-500 H:500-1800 (Optional 90-1800 stepless) |

|

Turret/tool post |

- |

Electric 4 position |

|

Tool size |

mm |

25 x 25 |

|

X axis travel |

mm |

230 |

|

Z axis travel |

mm |

750/1000/1500/2000 |

|

X axis rapid traverse |

mm/min |

6000 |

|

Z axis rapid traverse |

mm/min |

8000 |

|

Tailstock quill diameter |

mm |

65 |

|

Tailstock quill taper |

- |

MT4 |

|

Tailstock quill travel |

mm |

130 |

|

Main spindle motor |

kw |

4 |

|

Coolant pump motor |

kw |

0.09 |

|

Weight for 750 |

kg |

1700 |

|

Weight for 1000 |

kg |

1800 |

|

Weight for 1500 |

kg |

1900 |

|

Weight for 2000 |

kg |

2000 |

|

Dimension for 750 |

mm |

2200x1650x1700 |

|

Dimension for 1000 |

mm |

2500x1650x1700 |

|

Dimension for 1500 |

mm |

3000x1650x1700 |

|

Dimension for 2000 |

mm |

3500x1650x1700 |

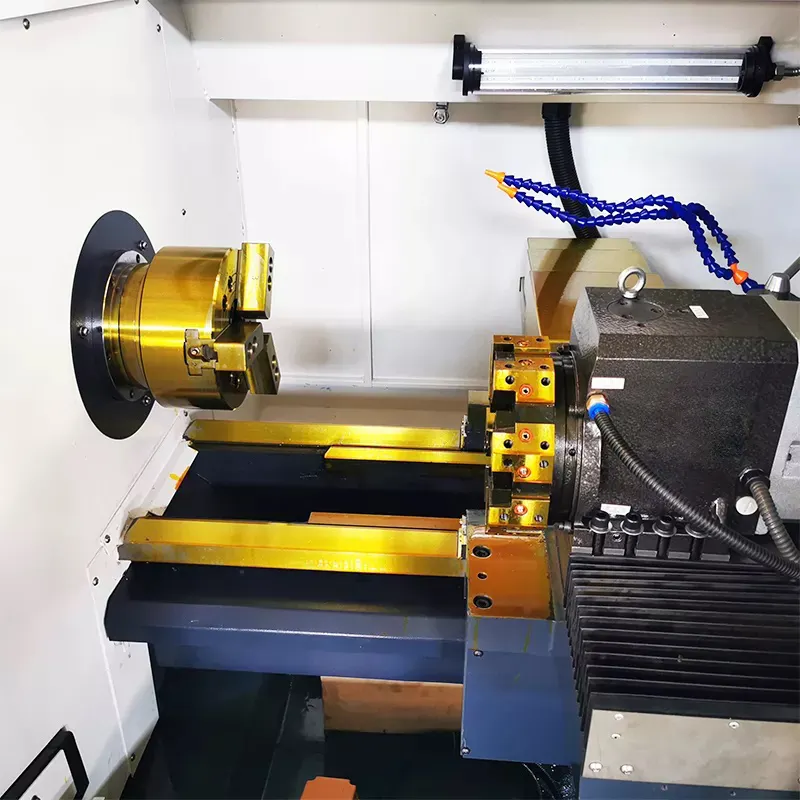

STANDARD CONFIGURATION

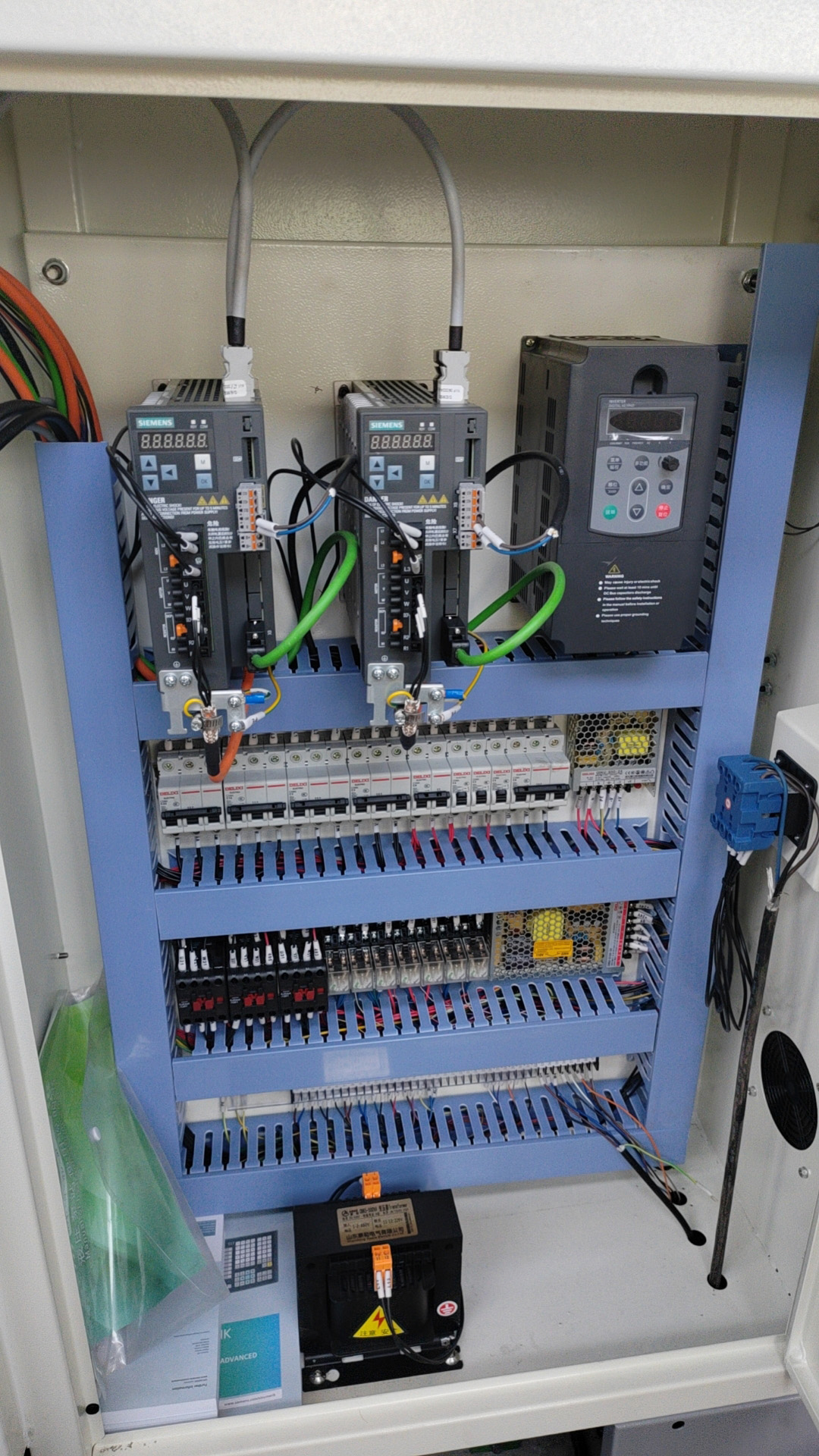

1) System:GSK, servo motor and drive.

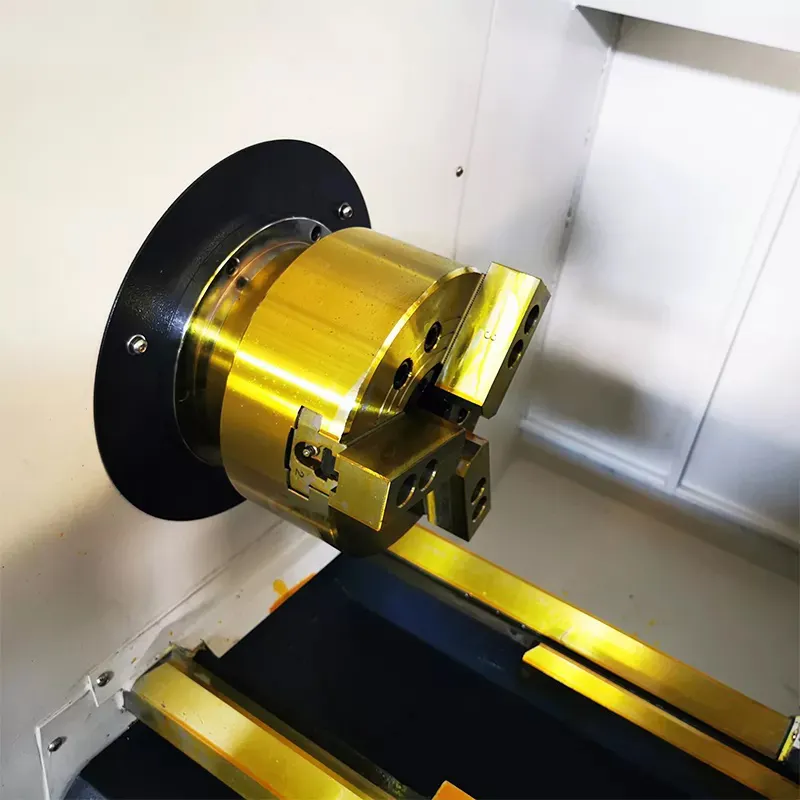

2) Manual 3-jaw chuck.

3) Four station electric tool post .

4) Manual tailstock;

5) Cooling system.

6) Lighten system;

7) Automatic lubrication system.

OPTIONAL CONFIGURATION

1) CNC system: Siemens, Fanuc, KND, etc。

2)Hydraulic chuck, pneumatic chuck .

3)Hydraulic tailstock, pneumatic tailstock.

4) 6/8station electric tool post.

5)Automatic bar feeder.